GIN CRAFTING

Traditionally crafted gin with an innovative twist

Inspired by the natural beauty of the Cotswolds and produced with the innovative skills of our distilling team, our award-winning Cotswolds Dry Gin is created with maximum flavour firmly at the top of our wish list.

-

01

STARTING WITH A BASE

To make our Cotswolds Dry Gin, we begin with a base alcohol made from wheat. This ‘neutral grain spirit’ is at 96% ABV and is completely flavourless. It is the blank canvas that we will add flavour to through our recipe of botanicals.

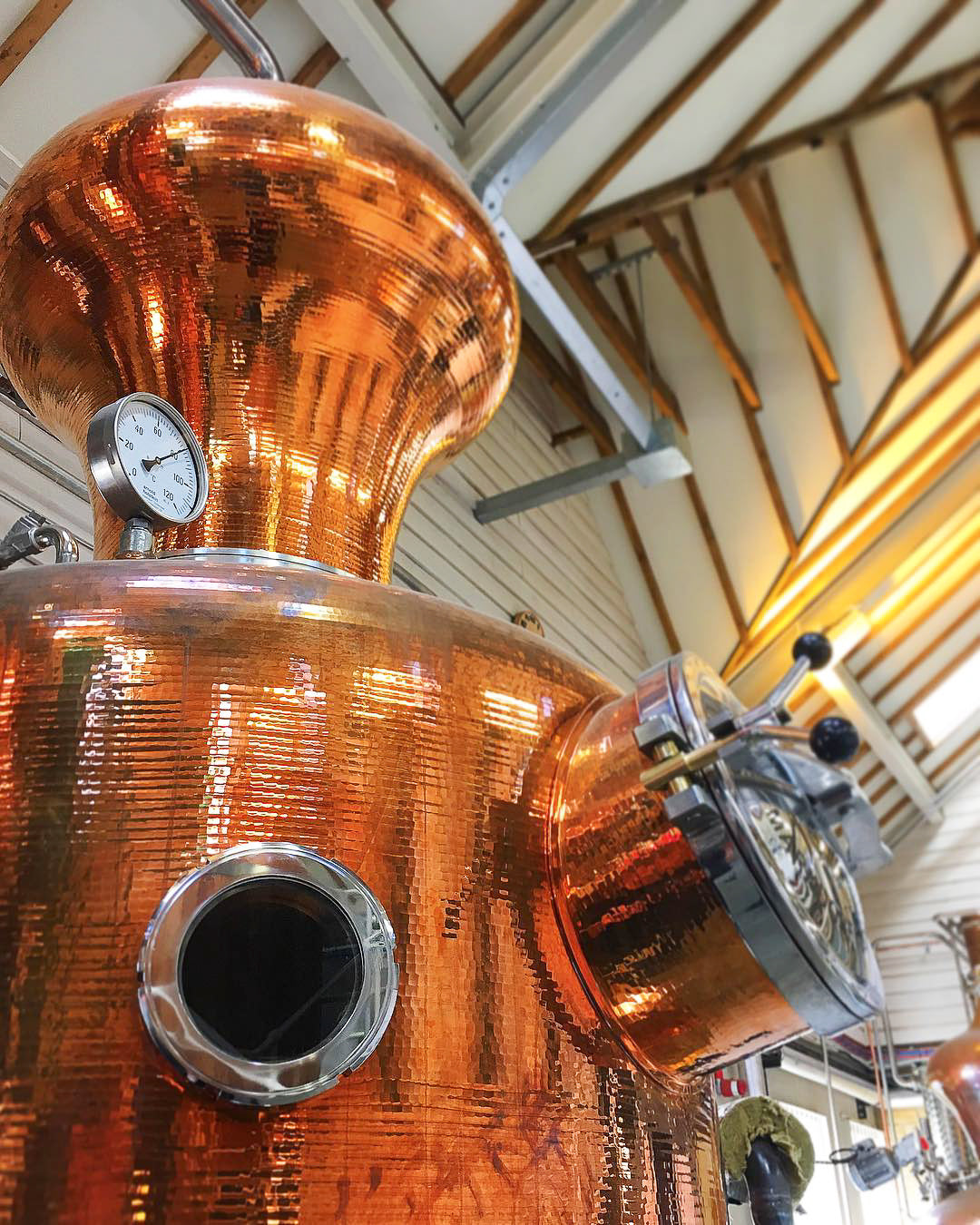

We place the neutral spirit and some water into our 500-litre copper pot still, Dolly, made by Arnold Holstein in Germany. It is a 500-litre pot still, but we only fill it ¾ full to make sure the vapours get plenty of contact with the copper during distillation.

-

02

DISTILLATION

We then add the base botanicals and leave these to macerate for 15 hours overnight. In the morning, we add the rest of the botanicals to the still. We use about ten times the average weight of botanicals and it’s the quantity of essential oils and botanical extract from them that gives our gin its characteristic richness.

Then we begin distillation, slowly boiling the contents of the still to drive off the vapours containing all the alcohol and the flavours. The first liquid to appear is called the ‘heads’ of the run – it is quite harsh and astringent, and is discarded. The middle or ‘heart’ of the run is the only gin we will use, and we run that off the still very slowly. The heart cut is relatively small – we’re just selecting the finest part of the run and avoiding any impurities. It means we only make a very small number of bottles from each run of the still, but the quality is fantastic.

-

03

RESTING AND REDUCING

The hearts, which are at 83% ABV, are then rested for 5 days to allow the various flavours to come together and settle in – nothing is rushed. All we then do is add filtered water to reduce the strength to 46% and the gin is then bottled here at the distillery. This is known as ‘single-shot distillation’ and it means we don’t add any more neutral grain spirit to the distilled batch to stretch out the gin and increase the number of bottles made from each run. Single-shot distillation is certainly a less efficient way of making gin, but we think it ensures the best possible flavour and quality.

We also don’t believe in chill-filtering our gin; this process removes oils and esters to make sure the gin stays crystal clear. We decided to leave the gin unfiltered to guarantee a rich and robust mouthfeel.

Whisky CRAFTING

Discover how we craft our range of single malt whiskies, from sourcing our locally grown barley to casking our new make spirit.